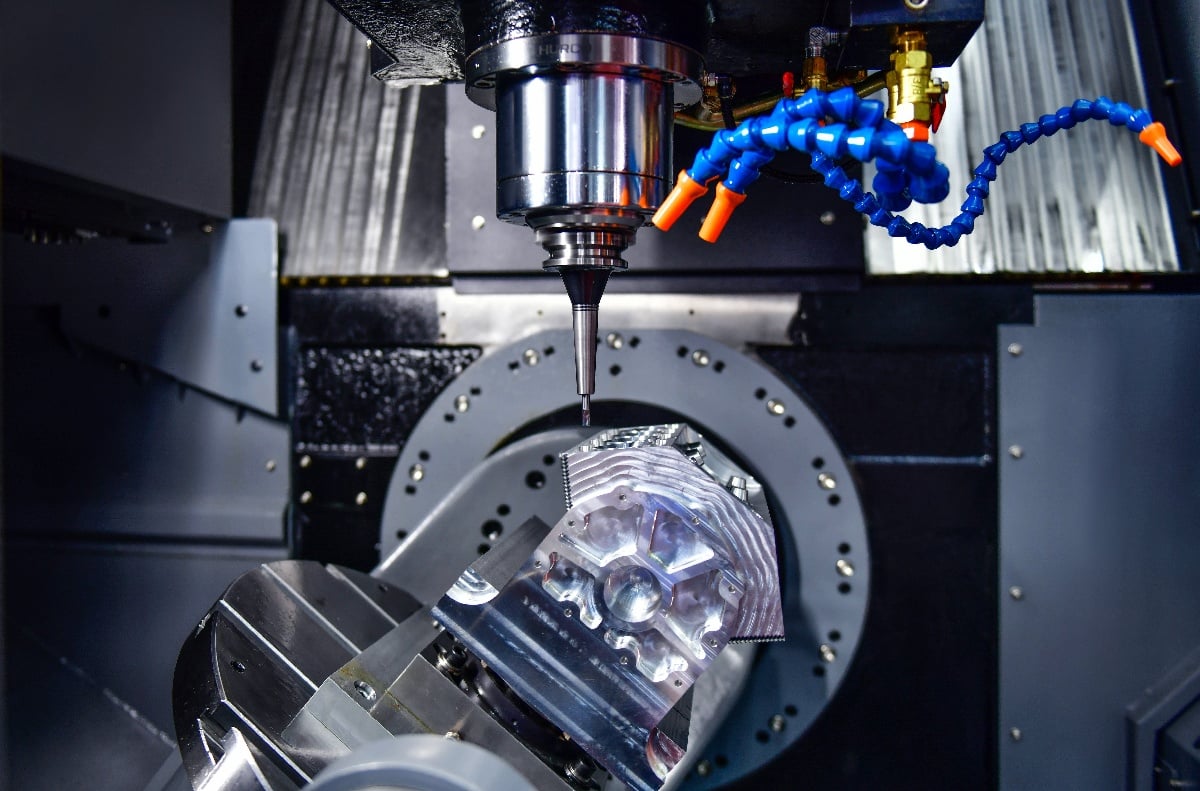

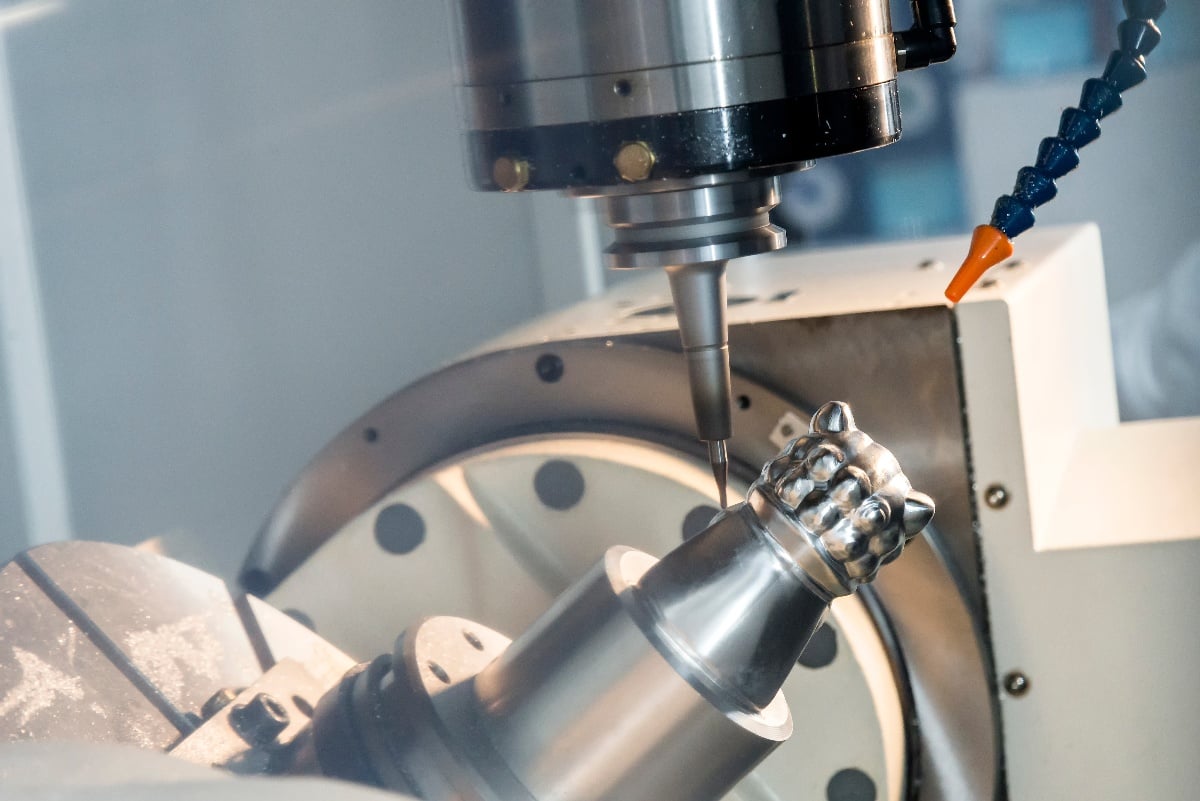

CNC milling is a versatile and widely used method for precision machining in the manufacturing industry. With the ability to create complex and intricate shapes, this technology has become an essential tool in the production of a wide range of products, from aerospace components to medical devices. In this guide, we will explore the basics of CNC milling, its applications, and the benefits it offers.

What is CNC Milling?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses a computer-controlled machine to remove material from a workpiece to create a desired shape. The machine uses a cutting tool to remove material from the workpiece. The process is guided by a computer program that specifies the dimension, shape, and surface finish of the final product. CNC milling machines can produce parts with a high degree of accuracy and offer high repeatability, this makes them ideal for high-volume production runs.

Applications of CNC Milling

Applications of CNC Milling

CNC milling is used in a wide range of industries, including aerospace, automotive, medical, and electronics, among others. Here are some examples of products that can be created using CNC milling:

-

Aerospace components: CNC milling is used to create complex and precise parts for aircraft, satellites, and spacecraft.

-

Repeatability: CNC milling machines can produce identical parts with a high degree of repeatability, making them ideal for high-volume production runs.

-

Versatility: CNC milling machines can produce a wide range of parts, from simple to complex shapes.

-

Efficiency: CNC milling machines can perform multiple operations in a single setup, reducing the need for manual labor and increasing production efficiency.

Benefits of CNC Milling

-

Accuracy: CNC milling machines can produce parts with a high degree of accuracy, with tolerances as low as 0.001 inches.

-

Repeatability: CNC milling machines can produce identical parts with a high degree of repeatability, making them ideal for high-volume production runs.

-

Versatility: CNC milling machines can produce a wide range of parts, from simple to complex shapes.

-

Efficiency: CNC milling machines can perform multiple operations in a single setup, reducing the need for manual labor and increasing production efficiency.

GET OUR CNC MACHINING INFO SHEET

CNC milling is a versatile and powerful technology that has revolutionized the manufacturing industry. With its ability to produce complex and precise parts, CNC milling has become an essential tool in the production of a wide range of products. Whether you are producing aerospace components, medical devices, or electronic components, CNC milling offers the accuracy, repeatability, and efficiency you need to stay competitive in today's marketplace.

Download our resource about CNC Machining here.