CNC machining is a vital process for manufacturing a broad range of goods, though choosing the best machine shop for your needs can be challenging and time-consuming. Whether searching online or asking for recommendations from other trusted providers, the following considerations can help you find the best shop for your project.

LOCAL CNC MACHINE SHOPS ARE IDEAL

Although not a necessity, a local CNC machine shop often offers more convenience. Using a local provider saves time and cost of shipping and it makes it easier to communicate with the machinists, resulting in increased efficiency of your project.

When sourcing a CNC machine shop online, choose one that provides live support to replicate the convenience of a local shop. Being able to speak directly with an expert greatly increases your chances of satisfaction and project success. Many online CNC machine shops will provide live support by phone, live chat, or email.

CNC MACHINE SHOP HANDLING YOUR PROJECT

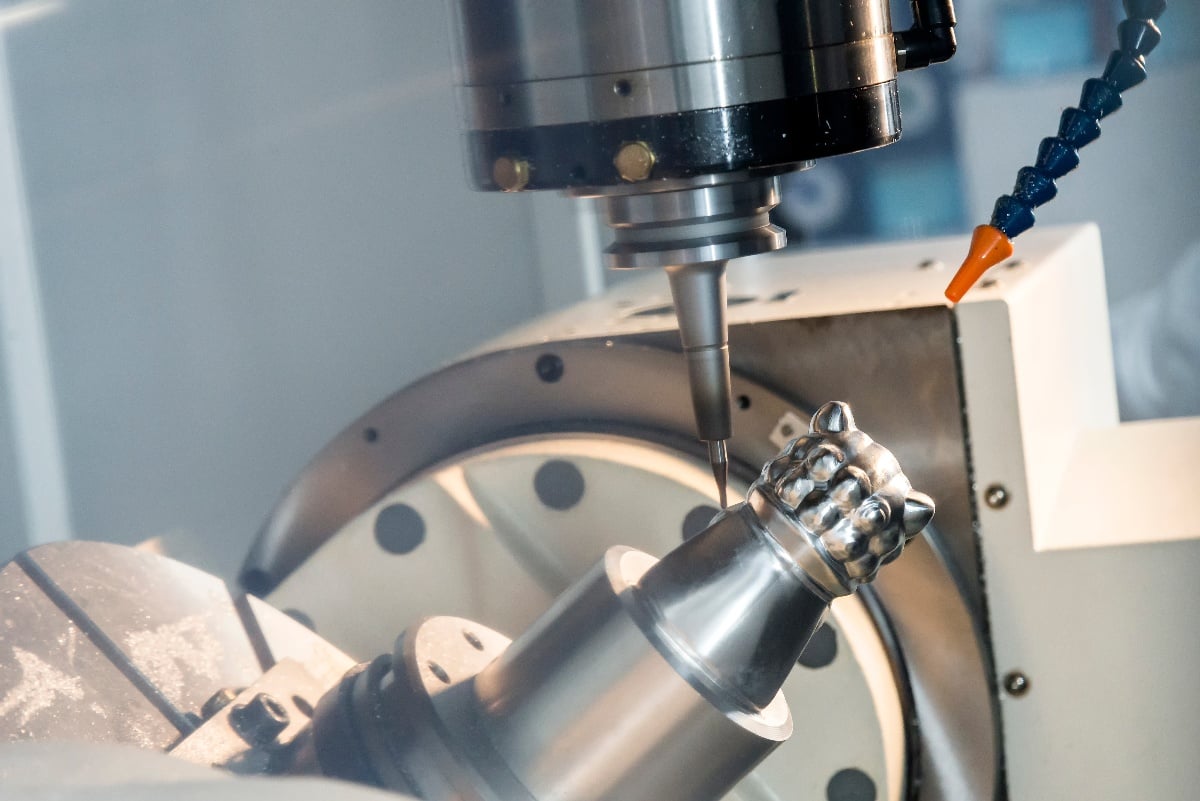

CNC machine shops often have different specialties, focusing on industries such as automotive or aerospace. It is therefore very important to find a shop that is capable of taking on your unique project. If they cannot fully meet your project’s needs, you may end up wasting time and money to correct subpar work.

To ascertain a shop’s capabilities, begin by asking about their equipment, work envelopes, and capacity. At a minimum, most shops should ideally be able to provide the following services:

-

Turning

-

Milling (3-axis)

-

Surface Grinding

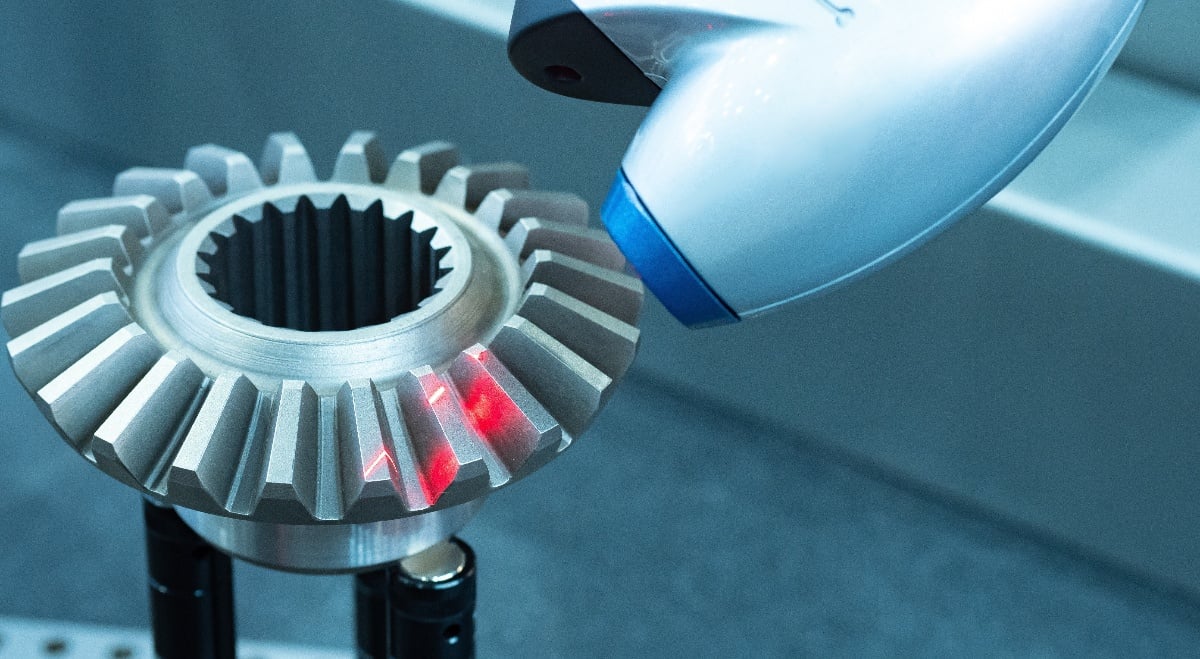

CNC machine shops that have a wide range of turning and milling machines with many axes will be able to handle more complex projects. These machines allow for tighter tolerances and a broader range of component sizes.

Shops that offer manual machining services may be ideal for smaller orders. This service gives machinists greater flexibility in the machining process, making it easier to be adaptable in the creation of customized parts.

Finally, ensure that the shop can handle the volume that you require. Some shops are only equipped to fulfill small-run production, while others have an order minimum and can only fulfill larger runs.

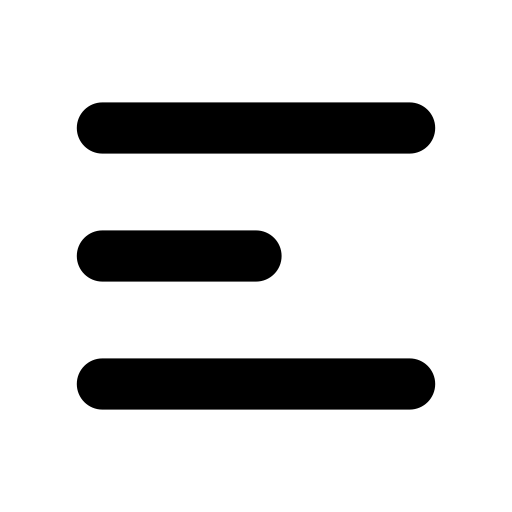

EXAMPLES OF PREVIOUS WORK

To be sure that the CNC machine shop you choose will be able to meet your needs, ask if they have worked on projects similar to yours in the past and request that they provide examples. If it appears that the shop has a history of successful projects, take some time to read customer testimonials. In particular, search for reputable clients giving positive reviews, as this indicates the shop’s high standing within your industry.

It is also a good idea to ask if the CNC machine shop provides quality guarantees. This will indicate that they are confident in their work while offering additional financial security in the case of unforeseen issues.

LONGEVITY OF THE PROJECT

When choosing the best CNC machine shop for your needs, it is important to consider the price risk versus the reward that you will get. While it may be tempting to opt for the shop with the most affordable prices, this is not always the best choice in the long run. Shops with higher quality equipment have a higher upfront cost, but they also produce better final products with less likelihood of production mistakes. Cheaper upfront costs, on the other hand, may result in hidden costs down the line due to slower production, manufacturing errors, or poor quality results.

WORK WITH PRO-TYPE INDUSTRIES FOR CNC MACHINING

Pro-Type Industries is dedicated to quality assurance and is ISO 9001:2015-certified. We are equipped with state-of-the-art CNC machinery to meet the needs of clients in a diverse range of industries, from Aerospace to Commercial Electronics. To work with us on your next project, request a quote or contact our team.